homemade wood lathe plans pdf

Homemade Wood Lathe Plans⁚ A Comprehensive Guide

This comprehensive guide provides detailed instructions and plans for building your own homemade wood lathe. Discover the benefits of crafting a custom lathe, explore essential tools and materials, and follow a step-by-step construction guide. Learn how to build the lathe bed, headstock, tailstock, tool rest, and connect the motor for speed control. Explore safety precautions and tips for using your new lathe, along with inspiring project ideas to get you started.

Introduction

The allure of crafting beautiful and functional woodturning projects often leads woodworkers to the world of lathes. While commercially available lathes offer convenience and precision, building your own homemade wood lathe provides a rewarding experience and a unique sense of accomplishment. This comprehensive guide offers detailed plans and instructions to help you construct a robust and reliable lathe from scratch, empowering you to transform your woodworking aspirations into reality.

This guide will walk you through every step of the process, from selecting the right materials and tools to assembling the lathe’s key components. You’ll learn how to build a sturdy lathe bed, a precise headstock for holding your workpieces, a reliable tailstock for supporting the other end, and a versatile tool rest for shaping your creations. By following these instructions, you’ll gain a deep understanding of lathe construction and design, enabling you to build a custom lathe tailored to your specific needs and preferences.

Benefits of Building a Homemade Wood Lathe

Building your own wood lathe offers a range of advantages over purchasing a pre-made model. First and foremost, it allows you to tailor the lathe to your specific needs and preferences. You can choose the size, design, and features that best suit your woodworking style and the projects you intend to undertake. This personalized approach ensures a lathe that fits perfectly in your workshop and meets your unique requirements.

Furthermore, building a homemade lathe provides a deep understanding of its mechanics and operation. You’ll gain valuable insights into the lathe’s construction, allowing you to troubleshoot and repair any potential issues with confidence. This hands-on experience will also enhance your woodworking skills and knowledge, making you a more skilled and informed woodworker. The process of building a lathe can be incredibly rewarding, giving you a sense of accomplishment and pride in crafting a functional piece of woodworking equipment with your own hands.

Essential Tools and Materials

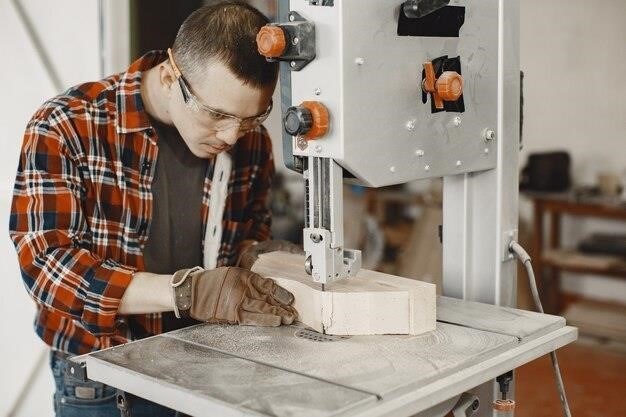

To embark on your homemade wood lathe project, you’ll need a selection of essential tools and materials. These include basic woodworking tools such as a saw, hammer, screwdriver, drill, and measuring tape. You’ll also need specific tools for metalworking, such as a metal file, drill bits, and possibly a welding torch.

The primary material for your lathe will be wood, preferably hardwood like oak or maple for durability and stability. You’ll also need various metal components, including bearings, shafts, and bolts. Consider sourcing a suitable motor for power, which can be a salvaged washing machine motor or a dedicated lathe motor.

Safety gear is crucial throughout the construction process. This includes safety glasses, gloves, and a dust mask to protect yourself from potential hazards. Remember to consult the specific plans you’re using for a comprehensive list of tools and materials required for your particular lathe design.

Step-by-Step Construction Guide

Building a homemade wood lathe is a rewarding project that requires careful planning and precise execution. Most plans will guide you through a series of steps, starting with the lathe bed, which serves as the foundation for the entire machine. This usually involves cutting and assembling wooden beams to create a sturdy and level base.

Next, you’ll move on to constructing the headstock, which holds the motor and spindle. This component requires accurate drilling and fitting of bearings to ensure smooth rotation. The tailstock, located at the opposite end of the lathe bed, supports the workpiece during turning and is typically built with a sliding mechanism for adjusting its position.

Once the bed, headstock, and tailstock are complete, you’ll need to assemble the tool rest. This crucial component provides a stable platform for holding turning tools while you work. Finally, you’ll connect the motor and speed control system to bring your homemade lathe to life.

Building the Lathe Bed

The lathe bed is the foundation of your homemade lathe, providing a stable platform for the headstock, tailstock, and tool rest. You’ll typically start by cutting and assembling wooden beams to create a sturdy and level base. Most plans recommend using hardwood like oak or maple for the bed, as these woods are known for their strength and durability. The bed should be long enough to accommodate the length of your workpieces and wide enough to provide stability.

To ensure a smooth and even surface for your lathe, it’s important to carefully plane and sand the bed. You may also want to consider adding a layer of epoxy resin to the bed for added durability and protection against moisture. Once the bed is assembled, you’ll need to attach the headstock and tailstock, ensuring that they are securely mounted and aligned.

The lathe bed is the foundation of your homemade lathe, providing a stable platform for the headstock, tailstock, and tool rest. You’ll typically start by cutting and assembling wooden beams to create a sturdy and level base.

Creating the Headstock

The headstock houses the motor and spindle, which rotates the workpiece. It’s a crucial component of your homemade lathe, and its design plays a significant role in the lathe’s performance and accuracy. Many plans call for a sturdy wooden frame to support the motor and spindle, often using hardwood like oak or maple for its strength and resistance to warping.

The spindle is typically made from a steel rod or shaft, mounted on bearings to ensure smooth rotation. You’ll need to secure the motor to the headstock frame, making sure that it’s aligned with the spindle. You’ll also need to incorporate a mechanism to control the speed of the motor, often using a variable speed control system.

To ensure accurate rotation, it’s essential to use a method for mounting the spindle that minimizes wobble. Some plans utilize a bearing system that allows the spindle to rotate freely with minimal friction. Others use a combination of bearings and a pulley system to transmit power from the motor to the spindle.

Constructing the Tailstock

The tailstock is the opposite end of the lathe from the headstock and plays a vital role in supporting and stabilizing the workpiece during turning. It’s typically a sturdy structure that slides along the lathe bed, allowing you to position it at various distances from the headstock to accommodate different workpiece lengths.

The tailstock often incorporates a mechanism for clamping the workpiece, usually a live center that fits into a tapered hole at the end of the workpiece. A live center has a bearing that rotates with the workpiece, reducing friction and ensuring smooth turning. The tailstock also typically includes a mechanism for adjusting the pressure applied to the workpiece, allowing you to fine-tune the support for different materials and sizes.

The tailstock can be constructed from various materials, including wood, metal, or a combination of both. Wood is often used for the frame, while metal is used for the live center and other components. It’s crucial to ensure that the tailstock is securely mounted to the lathe bed and aligns with the headstock to ensure accurate turning.

Assembling the Tool Rest

The tool rest is a crucial component of a wood lathe, providing a stable platform for holding and guiding your turning tools while you work. It’s typically positioned close to the workpiece and can be adjusted vertically and horizontally to accommodate different workpiece sizes and turning operations.

A well-designed tool rest is essential for safe and precise turning. It should be sturdy and rigid to prevent vibration and movement during use, and the surface should be smooth and flat to ensure smooth tool movement. The tool rest often includes a mechanism for clamping the tool in place, preventing it from slipping or moving during turning.

The tool rest can be constructed from various materials, including wood, metal, or a combination of both. Wood is often used for the base and support, while metal is used for the tool holder and other components. It’s crucial to ensure that the tool rest is securely mounted to the lathe bed and can be easily adjusted to accommodate different turning tasks.

Connecting the Motor and Speed Control

The motor is the heart of your homemade lathe, providing the power to spin the workpiece. Choosing the right motor is crucial for achieving the desired turning speed and power. A common option is a washing machine motor, readily available and often suitable for woodworking applications. However, consider the motor’s power output and speed range to ensure it’s adequate for your intended turning projects.

A variable speed control is essential for precise control over the lathe’s speed. This allows you to adjust the turning speed depending on the type of wood, tool, and project. Variable speed controllers can be purchased separately or included as part of a motor package. They often have a dial or buttons for adjusting the speed and may incorporate features like safety mechanisms and overload protection.

Connecting the motor and speed control involves wiring the components together, ensuring proper connections and grounding for safety. Refer to wiring diagrams and instructions for your specific motor and speed control to avoid electrical hazards. Securely mount the motor to the lathe bed, ensuring it’s properly aligned and balanced to minimize vibration and noise during operation.

Safety Precautions

While building and using a homemade wood lathe offers a rewarding experience, safety should always be a top priority. Before starting any project, familiarize yourself with proper safety procedures and equip yourself with the necessary safety gear; This includes wearing safety glasses to protect your eyes from flying debris, hearing protection to safeguard your ears from loud noises, and a dust mask to prevent inhaling wood dust. Always wear close-fitting clothing and avoid loose jewelry or clothing that could get caught in the rotating parts.

When operating the lathe, never leave it unattended while it’s running. Keep your hands and fingers away from the spinning workpiece and rotating parts. Use a tool rest to support your turning tools and ensure they are securely held. Always maintain a clear workspace around the lathe, free from clutter and distractions. Ensure the lathe is properly grounded to prevent electrical shocks. Before starting the lathe, check for any loose or damaged parts and make necessary repairs. If you encounter any problems or feel unsure about anything, consult a professional woodworker or lathe operator for guidance.

Tips for Using Your Homemade Lathe

Mastering the art of woodturning on your homemade lathe involves a few key tips to ensure smooth operation and stunning results. Start by choosing the right wood for your project. Hardwoods like maple, cherry, and walnut are excellent for turning due to their strength and stability, while softer woods like pine and basswood are easier to work with for beginners. When mounting your workpiece, ensure it’s securely centered and clamped to the lathe bed. Always use sharp turning tools, as dull tools can cause uneven cuts and increase the risk of accidents. Start with a light touch when turning and gradually increase pressure as you gain confidence.

Maintain a steady speed while turning, adjusting the lathe’s motor speed to match the size and hardness of your workpiece. Avoid excessive pressure and allow the tools to do the work. Take your time and focus on smooth, controlled movements. Be mindful of the direction of grain in the wood and turn with the grain for smoother results. Remember to practice regularly and experiment with different techniques to hone your skills. With patience and dedication, you’ll be able to create beautiful and functional woodturning projects on your homemade lathe.

Project Ideas for Your New Lathe

The possibilities are endless with your newfound woodturning skills! Start with simple projects like wooden bowls, spindles, and ornaments to get a feel for the lathe. Challenge yourself with more intricate designs like chess pieces, decorative boxes, and custom furniture legs. Explore the world of woodturning pens, creating unique and personalized gifts. If you’re feeling adventurous, try your hand at woodturning hollow forms, creating vessels with intricate curves and hollow interiors. Don’t be afraid to experiment with different wood species and finishes to create truly one-of-a-kind pieces.

Consider turning useful items like wooden spoons, rolling pins, and cutting boards, adding a touch of handmade charm to your kitchen. With your newfound skills, you can create beautiful and functional pieces for your home or even sell your creations at craft fairs and online marketplaces. The world of woodturning is a fascinating journey, and your homemade lathe is the key to unlocking its creative possibilities. So, grab your tools, get inspired, and let your imagination run wild with your new woodturning adventures!

Building a homemade wood lathe is a rewarding project that combines woodworking skills with a touch of engineering ingenuity. The journey from planning to completion offers a sense of accomplishment and allows you to create a tool tailored to your specific needs; With your newly crafted lathe, you unlock a world of creative possibilities, turning simple wood into beautiful and functional objects. Whether you’re a seasoned woodworker or a curious beginner, the satisfaction of building and using your own lathe is truly unparalleled. So, embrace the challenge, follow the plans carefully, and enjoy the journey of crafting your own woodturning masterpiece.

Remember, safety should always be your top priority. Wear appropriate safety gear, work in a well-lit and ventilated area, and never operate the lathe without proper knowledge and training. With careful planning and execution, you can build a durable and reliable lathe that will serve you well for years to come. Embrace the spirit of DIY and enjoy the journey of turning your woodworking dreams into reality.